Services

Product development

The corporate skills of the Carlo Corazza Srl staff allow us to be the ideal partner for the development of new projects, in close collaboration with the customer: in fact, we recommend design details, tolerances, dimensions of the blanks, optimized machining to use standard tools (containing the production cost) or special tools to realize specific technical needs.

We are also able to support our customers with experience on advanced materials, heat treatments and hi-tech roofing technologies.

We can develop economic-productive analyzes to hit the necessary target price according to technologies and production lots, subsequently developing dedicated plants and systems.

The development of close collaborations and partnerships based on mutual trust and respect is our main objective.

We recall here all the services we offer to our customers, explained in detail below:

MACHINING WITH CUSTOMER PARTS

We are passionate about working for our partners; the culture of contracting is really ours!

Want to know how we do it?

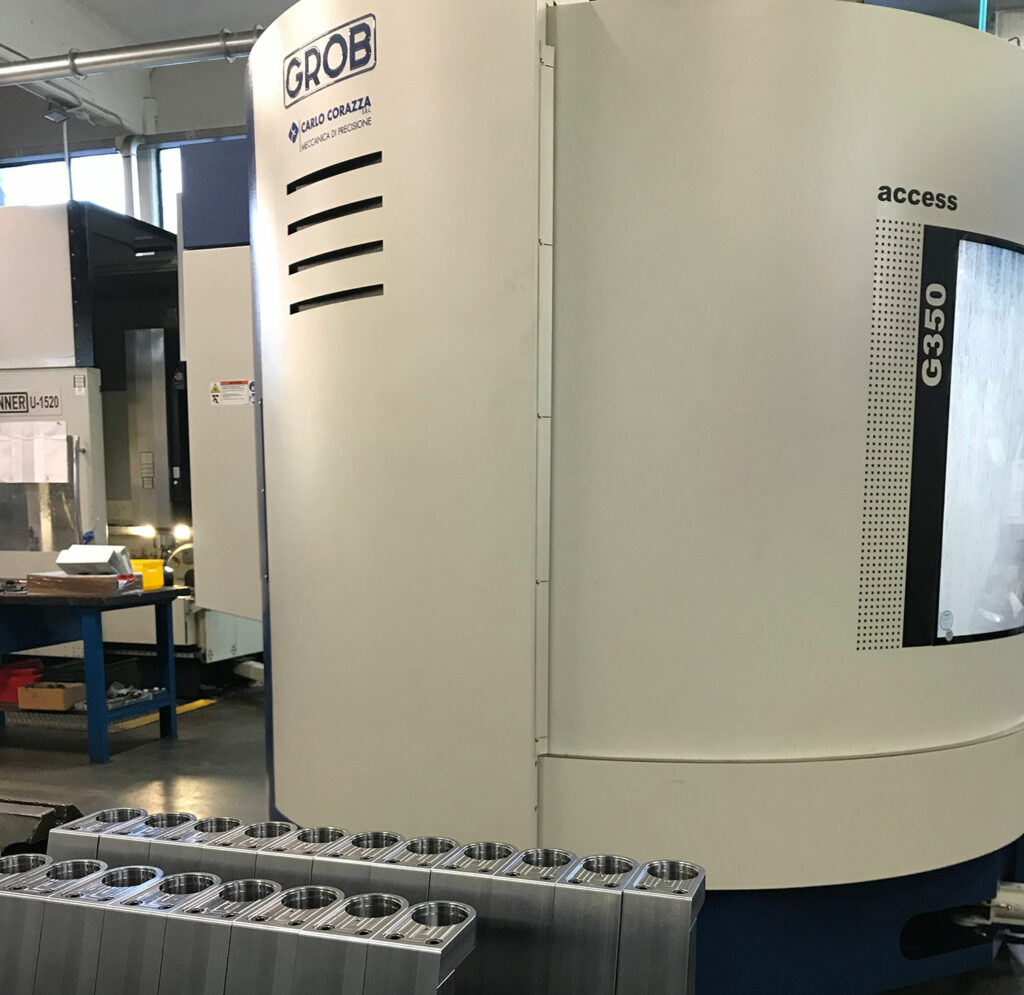

We operate through advanced CNC machining centers (Milling and Turning) of the latest generation, connected to the company network (LAN) and to the CAM department: the milling centers have 3, 4 and 5 axes, completed by multitasking lathes particularly suitable for processing materials high tech

All the precision CNC machining centers are connected to the company network (LAN) and receive the complex work cycles directly, set up by the technical office (CAM department), in order to maximize automation and therefore productivity, to the full advantage of delivery times and quality of the final product.

Fantastic? No, real. In Corazza you can!

CAD/CAM AND DESIGN

You expected it, didn’t you? But it wasn’t so obvious!

For us, designing means using advanced CAD/CAM systems with the most modern removal strategies.

Our CNC machines are connected to a CAD-CAM system.

For more complex processes, the technical office with the help of dedicated software (CAD-CAM) carries out the study and programming from the office.

An up-to-date networked computer system assists all activities relating to production, the quality system and company administration.

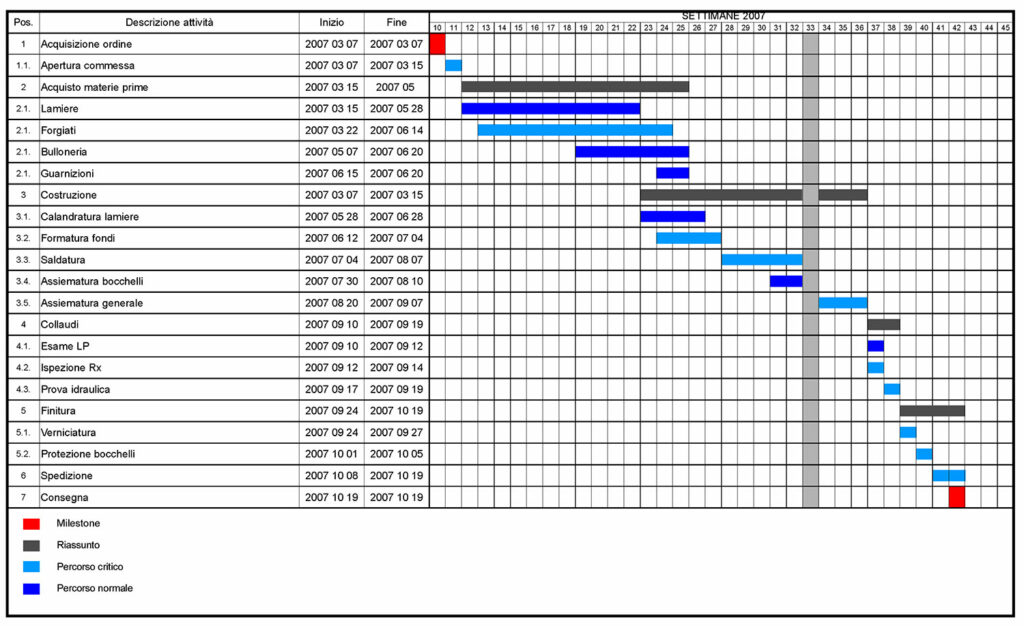

ORDER MANAGEMENT

Our philosophy is to satisfy market demands in a timely, flexible and competitive manner.

In addition to a company that only deals with precision mechanical machining, we are a company that carries out “turnkey” orders, as an express vocation and on broad delegation agreed with the client.

All this is due to the growing need to keep the production process under strict control in all its macro-phases.

INDUSTRIALIZATION

After a component has been subjected to intense industrial production cycles, the need often emerges for the customer to optimize its performance, reducing production costs, but without reducing overall quality.

Our team of specialists is ready to provide customers with the best solutions to combine high product yield performance with sustainable costs, proposing the adoption of processes and/or the use of alternative materials as well, and always guaranteeing high-level performance .

All this is made possible by our training in metallurgy, machining and metrology; combined with many years of experience in the most diversified sectors.

We believe it is essential to support our customers in their needs in order to be considered not just suppliers but partners.

INFORMATIZATION

In today’s frenzy, we know that without the help of interfaced management programs it is almost impossible to monitor a process effectively and efficiently, correctly respecting supply times.

Some of our customers use lean-production systems and constant monitoring of step-by-step production is therefore essential for them.

For this reason, continuous research into IT know-how is felt for us as a vital need rather than a casual opportunity.

And all of our activity is characterized by an IT key. We have software for administration, for the management and development of orders and for monitoring and finalizing production.

STRUCTURE ASSEMBLY

Really, we are able to manage the assembly of groups and sub-groups according to the customer’s specifications, thus achieving a complex set of machined, commercial elements by assembling them with a specific functional test. Beautiful thing!!

PARTS TESTING

The parts made are tested by us at the end of the production cycle in the metrology room according to statistical rules or customer rules. The tests can also be developed on groups and subgroups with equipment and customer specifications (we carry out leak tests and “go or no go” tests with dedicated tools).

WAREHOUSE AND SHIPPING

Quality production without top-level logistics is of no use to customers. We are very aware of it. This is why we dedicate ourselves carefully to this aspect of our business.

High-quality transport and deliveries involve in-depth knowledge of the needs of the sender and the recipient: together with our customers, we face a path of mutual understanding, so that the absolute priority becomes that of obtaining an optimal final result.

At the end of production, the goods are packed in our warehouses awaiting shipment to the customer.