Precision mechanics since 1970

Mechanical evolution according to Carlo Corazza

In our company, we’ve been working to promote innovation in the mechanical industry since the 1970s.

Over this time, we’ve proven to be resilient and able to manage problematic and sensitive situations, both regarding material supply, processing or finishes of any kind and all the way to customised solutions for individual components.

We are a reliable partner as we always follow three simple rules: we are meticulous, accurate, and on time.

This is why we feel involved in the mechanical evolution: it’s in our logo!

Processing areas

There are many areas in which we can be involved:

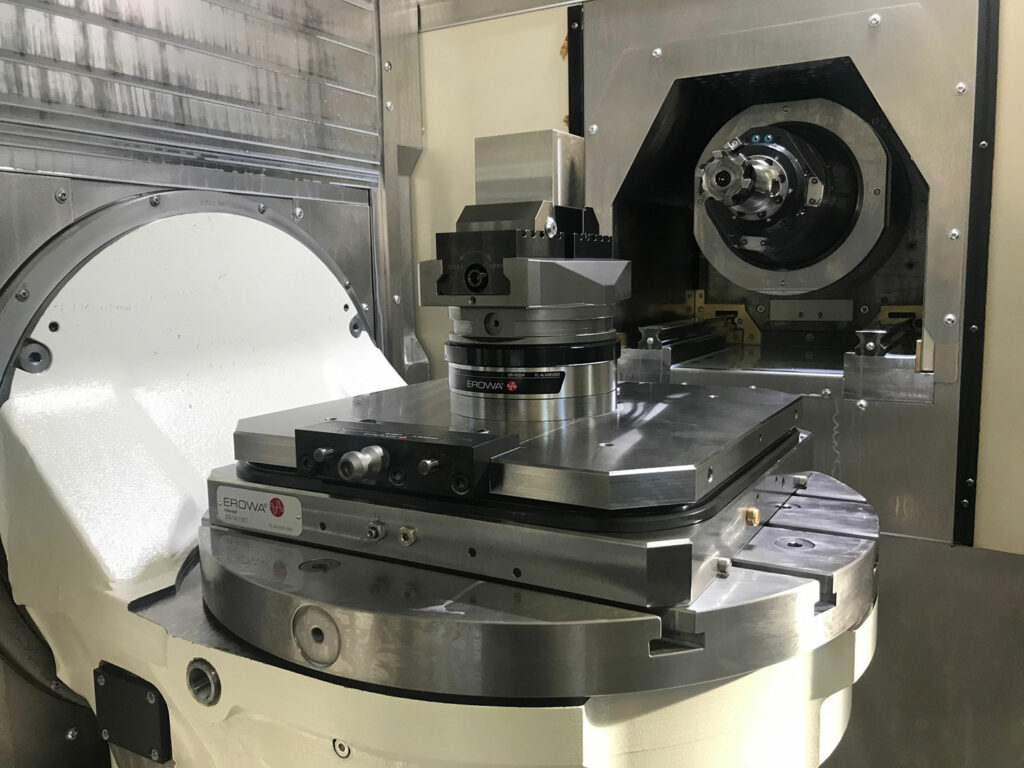

- Milling –Turning - Slotting

- Adjustment - Assemby

- Dimensional measurements

- Welding

- Grinding

- Lapping

- Polishing

- Peening

- Surface heat treatments

- Anodizing

- Brunishing, Phosohating, Galvanizing

- Nichel plating, Chrome, PVD

- Passivation

- Electro polishing

- Satin finish

- Paint

- Kolsterization

- Chemical nickel planting

- Hardening and Surface tratments

To protect our customers, the entire production process is certified ISO9001:2015 and monitored in real time with the help of advanced management software according to the specifications of industry 4.0. The materials we use are also certified, and detail is our passion: for example, we can manage specific special processes with procedures for parts in contact with food and pharmaceuticals (MOCA).